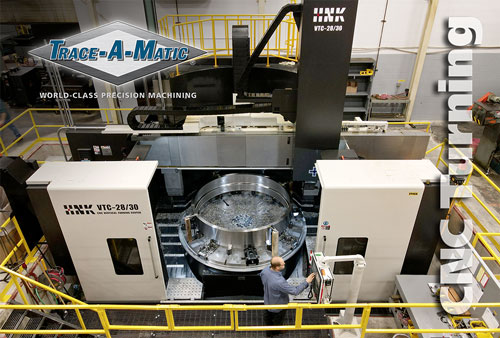

Precision Turning Parts

Trace-A-Matic’s arsenal of high precision horizontal and vertical CNC turning centers offers massive machining capacity and high production capability. Years of experience provide expert knowledge of hundreds of metal alloys, their characteristics, and how the material reacts when milling and turning the desired shape. Proper machine tool selection, cutting tool depth, milling drilling feed and speed, chip control, and high-pressure coolant are critical in controlling heat generation, which can cause part movement and tool deflection while removing material. This level of skill ensures world-class precision machining that meets or exceeds the most demanding tight tolerances.

The innovative Trace-A-Matic team is always available to cost-effectively guide you through the design and manufacturing process. Our goal is 100% customer satisfaction, providing AS 9100/ISO 9001:2015 certified quality machining resulting in good lead times, on-time delivery, and unmatched customer service.

Production Capabilities

Part Types:

Cylinders, hubs, casings, flanges, shafts, housings, spindles, axles, rollers, pump bodies, wheels, rotary couplings, specialty pressure vessels, downhole drilling components, and other cylindrical parts

Machining Parts Size:

Horizontal - 118” diameter x 78” tall work envelope

Vertical - 160” long x 35” diameter work envelope

Metal Types:

All standard metals,

aluminum, armor plate, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, Monel, nickel, Nitralloy, powdered metals, stainless steel, steel ,Stellite, titanium, Waspaloy, and many other superalloys

Material Types:

castings, forgings, fabricated weldments, billets, bar stock, plate, and sheet metal

Computer-Controlled Turning Operations:

Boring, cutting, drilling, facing, internal forming, knurling, necking, parting, shoulder facing, threading (external, internal), and turning (contour, form, taper, straight)

Industries Served:

Aerospace, Automotive Industry, Defense, Food Processing, Forging, Foundry, Heavy Equipment, Infrastructure, Marine, Medical Equipment, Military, Mining, Oil and Gas, Power Generation, Space | Rocket, and Transportation

Machine Brands:

DMG Mori, Doosan, Dynamic KTM, HNK, Hyundai Wia, Mazak, Mori Seiki, New Century, Okuma & Howa, Samsung, Smart, Twin Merit, and Weiler - Please refer to our Equipment List for specific lathe information and wide-ranging capabilities.

CNC Turning Gallery

Large Turned Ring

CNC Lathe With Live Tools

Axles Turning

High-Quality Surface Finish

Precision Turned Threads

Turned Assembly

Brass Turning

Titanium Turned Casing

In the manufacturing world, where precision reigns supreme, there’s a quiet hero: CNC turning. While it may seem like a series of mundane operations at first glance, computer numerically controlled turning is crucial in creating countless components that drive various industries forward.

At the heart of CNC turning lies the precise rotation of the workpiece. Simultaneously, a cutting tool, guided by sophisticated machinery, moves across the surface, sculpting the raw material into intricate shapes. This motion interaction is the essence of the CNC turning process, a cornerstone of subtractive manufacturing.

In the subtractive manufacturing process, material is removed from a solid block to achieve the desired shape. CNC turning and its sibling, CNC milling, are the dynamic duo responsible for this feat. Together, they form the backbone of modern manufacturing, producing parts with unparalleled accuracy and efficiency.

From essential components to intricate assemblies, CNC turning and milling are adaptable tools capable of shaping a broad spectrum of materials to precise specifications. Whether aluminum for aerospace applications or steel for automotive parts, these processes deliver top-notch results, sparking curiosity about their limitless potential.

Within CNC turning, a diverse array of operations exist, each tailored to specific requirements. Facing, boring, and threading are just a few examples of CNC turning operations. Each operation brings challenges and opportunities, allowing manufacturers to fine-tune their processes for optimal performance.

As technology propels forward and industries transform, the significance of CNC turning services in manufacturing parts cannot be overstated. It is the unsung hero, quietly shaping the world around us one rotation at a time. So, the next time you admire a finely crafted component, take a moment to acknowledge the intricate work of CNC turning and its pivotal role in bringing ideas to life, enlightening you about its profound impact.

Other CNC machining services: 5-Axis Machining, Multi-Axis Machining, Horizontal Milling, Vertical CNC Milling, Horizontal Turning, Vertical Turning, CNC Engineering, CNC Inspection, and Special Machining Process

All product names, trademarks, and registered trademarks are the property of their respective owners.