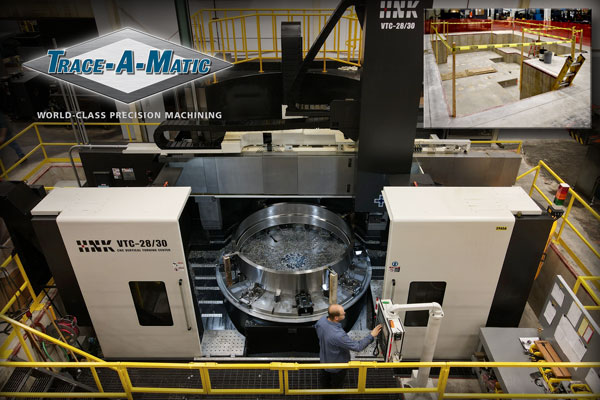

New HNK VTC-28/30 provides a massive 118” cutting diameter

Trace-A-Matic has installed a new HNK VTC-28/30 vertical turning center at their Brookfield, WI location. The HNK features a 60HP, 130RPM table with a 44,000-pound load capacity and a 25HP live spindle to support tapping and other machining operations. The installation increases the company’s turning capability to a cutting diameter of 118.1” and height of 78.67”. The new turning center will precisely machine large industrial rings, forgings, and castings for their military, water, oil and gas, and space customers. The center resides in a 75” recessed area constructed explicitly for the installation.

“The new machine expands Trace-A-Matic’s turning capabilities and capacity to meet the growing demand of our customers,” Thorsten Wienss, CEO at Trace-A-Matic, said in a statement. “We performed a pit-type installation on this center due to the restriction of a concrete ceiling at that particular facility. It was quite an undertaking, but the results turned out extremely well!”

About Trace-A-Matic Corporation

For over 50 years, Trace-A-Matic Corp. has been producing precision machined CNC (computer numerical control) components and assemblies for manufacturers in the aerospace, defense, food processing, heavy equipment, medical equipment, oil and gas, power generation, transportation, and general industry markets. The company’s state-of-the-art manufacturing facilities in WI and TX use the latest CNC machining technologies to produce complex and intricate components that meet or exceed the most critical tolerances. Products machined from castings, weldments, forgings, tubing, and bar stock range from 1 pound to 15,000 pounds.