Turn-Key Power Generation Solutions

Trace-A-Matic partners with power generation customers to provide turn-key solutions for their long-term manufacturing programs. Our programmatic approach offers complete control from start to finish over prototype development, procurement, product quality, kitting and assembly, inventory control, and on-time delivery of generator parts and assemblies. Trust Trace-A-Matic to get it right the first time — And every time!

Supported Power Sources: Fossil Fuel, Wind, Hydroelectric, Nuclear, Solar, Geothermal, and Biomass

- Generator Engines - Piston Heads, Connecting Rods, and Cylinder Liners

- Steam and Gas Turbines - Compressor Casings and Supporting Parts

- Large Armature Shafts

- Stator Housings

- Gearbox Components

- Pump Housings

- Large Valve Components

- Oil and Fuel Pumps

- Wicket Gates

- Oil and Fuel Filter Bases

- Large Bearing Inner and Outer Races

- Couplings and Fittings

- Precision Static and Moving Parts

- ISO 9001:2015 certified built on a rigorous QMS

- Precision CNC machined parts from castings, forgings, fabricated weldments, tubing, billets, plate, sheet metal, and bar stock weighing up to 15,000 pounds.

- We are experts at machining aluminum, armor plate, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, Monel, nickel, Nitralloy, powdered metals, stainless steel, Stellite, titanium, Waspaloy, and many other superalloys.

- Trace-A-Matic provides complete manufacturing solutions with an extensive managed network of subcontractors and material suppliers.

Trace-A-Matic’s machine shop services include CNC engineering, 3D CAD modeling, CNC CAM programming, virtual machining, reverse engineering, 3D printing rapid prototypes, multi-axis machining, 5-axis machining, 4-axis machining, 3-axis machining, CNC milling (vertical and horizontal), CNC lathe/turning (vertical and horizontal), and Coordinate Measuring Machines - CMM inspection.

Managed services include thermal processes (heat treating, induction hardening, flame hardening, nitride, cryogenic stress relieving) and coatings (chrome plating, anodize, hard coat anodize, tiodize, phosphating, painting). Also, deep hole processing (gun drilling, honing), welding (MIG, TIG, friction welding), and grinding (OD/ID, Blanchard, surface, and jig).

We have a massive manufacturing capacity of 300,000+ sq. ft. climate-controlled environment, 150+ precision machining centers, 200+ highly-skilled workforce with Brookfield, WI, and Houston, TX locations, serving the US and international customers since 1968. Take a quick video tour of Trace-A-Matic - (2 minutes, 35 seconds):

Engine and Turbine Power Generation

Fossil fuel generators use combusted natural gas, diesel, and gas to create mechanical energy converted into electrical energy by electromagnetic induction. The main reason for generator operation is to combat power outages or if additional electricity is needed.

- Engine

- Alternator

- Fuel System (NG supply lines)

- Voltage Regulator

- Cooling and Exhaust Systems

- Lubrication System

- Control Panel (generator settings)

- Main Frame

- Battery Charger (located on the backside)

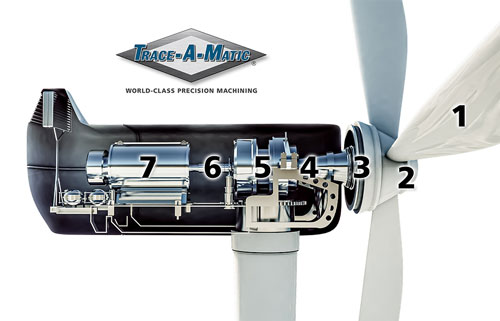

Wind Turbine Power Generation

Wind generators use the wind to create mechanical energy converted into electrical energy by electromagnetic induction.

- Blade

- Rotor

- Hub

- Low-Speed Shaft

- Gearbox

- High-Speed Shaft

- Generator

Download the Power Generation Solutions PDF

Download the Power Generation Solutions PDF