Consistently Delivering Machining Excellence

Trace-A-Matic is a CNC machine shop recognized for world-class precision machining by leading OEMs. Our manufacturing takes place upon a solid foundation of quality control, backed by a comprehensive AS 9100D / ISO 9001:2015 quality system. Every new part order enters into our engineering evaluation process identifying and addressing all foreseeable issues before production. Our engineers use these findings to form a plan aligning the proper inspection procedures to ensure your machined parts and assemblies meet or exceed every specification. Planning includes the instruments to be used, the need and frequency of in-process inspections, process certificate verification, as well as final inspection requirements. We understand the incredible responsibility you entrust upon us when manufacturing your mission-critical components and the safety of the people that depend upon them.

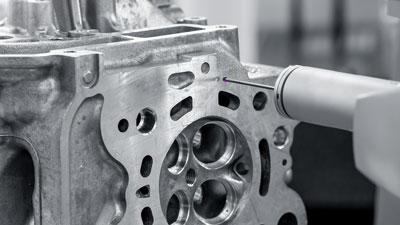

Trace-A-Matic uses state-of-the-art, fully automated CMMs (Coordinate Measuring Machines), Romer arms, and powerful PC-DMIS (Personal Computer - Dimensional Measuring Interface Standard) software to measure and verify critical external and internal part dimensions, complex geometry, overall machine tool output, and other vital features as specified. Machinists and quality assurance people use gages and other instruments for in-process testing and verification. The company manages over 6,000 gages used in a wide range of machining process validation. An outside IEC 17025 accredited calibration facility oversees our rigorous calibration system. All of our facilities are climate controlled at 70°F ±2° with relative humidity below 40% to ensure a stable testing and manufacturing environment.

As a Tier 1 source, Trace-A-Matic will manage and provide inspection on all aspects of your manufacturing process. Including Thermal: heat treating, induction hardening | Coatings: chrome, plating, anodize, phosphating, painting | EDM (Electrical Discharge Machining): wire, sinker | Deep Hole Processing: gun drilling, honing | Gear Cutting and Grinding: helical, spline | Surface Finish: superfinishing, micromachining, microfinishing | Machined Part Balancing | Porosity Impregnation: castings, powdered metal, weldments | Welding: traditional, friction.

For the highest quality parts, made to print, the first time, Trace-A-Matic is your world-class precision machine shop!

Inspection Capabilities Summary

Part Size:

Bridge CMM Capacity of 79” x 130” x 59” at 14,300 lbs. and Romer Arm Reach of 157.5”

Machined Feature Inspection:

External and internal dimensions, external and internal geometry, boring, counterboring, countersinking, drilling, facing, gear hobbing, internal forming, knurling, milling, necking, parting, pocketing, profiling, reaming, shoulder facing, spline, tapping, threading (external, internal), turning (contour, form, taper, straight), thread milling, surface finishing, and other features as specified

Equipment Brands:

Hexagon, ROMER, Mitutoyo, Starrett, and various others - Please refer to our Equipment List for CMM and Romer Arm information and capabilities.

Additional Testing Services:

Non-Destructive Testing, Pressure Testing, Millipore Testing, and Fatigue Testing

CMM - Coordinate Measuring Machine Overview

A process engineer or quality technician generates CMM programming to read and verify critical component markers established by our engineering evaluation process. Machined parts or assemblies rest upon or are affixed to the stationary granite measurement table, or held in place by use of a fixture. The CMM probe travels on the Z, Y, and X-axis precisely interacting with the part as the PC-DMIS programming dictates, recording every marker and bringing alert if an issue is present. Machining parameter adjustments quickly result when observing variation in the machining process. The CMM testing process successfully measures and verifies even the most complicated part geometry.

CMM Anatomy

- Probe - The instrument that travels on the Z, X, and Y-axis that comes in physical contact with the part

- Vertical Ram - Holds the probe and moves on the Z-axis (up and down)

- Component - The machined part or assembly the CMM machine is measuring

- Granite Measurement Table - An extremely heavy-duty, stationary bed that holds parts and fixtures for inspection

- Bridge - Allows the probe and ram to travel on the Y-axis (left and right)

- Carriage - Travels the length of the granite measurement table on the X-axis (front and back), transporting the bridge, vertical slide, ram, and probe

- Pendant/Jogbox - The interface a quality technician uses to manually program and control how a CMM operates

Inspection Definitions

- Calibration - Comparison of an instrument against a known standard. Calibration includes repeatability checks, adjustments, etc.

- FAI - First Article Inspection

- FMEA - Failure Modes Effects Analysis

- Instruments - Measuring or test equipment, either mechanical or electrical; this includes “tool,” “gauge,” “test equipment,” and “standards.”

- Instrument Identifications - All Trace-A-Matic standards and instruments used for product acceptance are assigned a unique identification number. Devices may be marked, scribed, labeled, or color-coded with the I.D. number.

- ISIR - Initial Sample Inspection Report

- PPAP - Production Part Approval Process

- Product Acceptance Inspection - The inspection operation, after which the product goes directly to the internal/external customer or into stock, is termed “Product Acceptance.”

- Soft Gages - Gages machined in-house for a specific product or characteristics.

- Source Inspection - A customer representative visits Trace-A-Matic to serve as an outside quality inspector.

- Standard - Serves as a master device used for purposes of comparison of known dimensions or characteristics.

- Verification - A functional check of an instrument checking the instrument against a calibrated standard. Verification does not involve repeatability checks or adjustments.

- Virtual Inspection - A customer representative performs a quality inspection at Trace-A-Matic remotely over a secure communication platform.

CNC Inspection Photo Gallery

Complex Geometry Inspection

Dimension Verification

In-Process Testing

CMM Part Fixturing

CNC Inspection Video

Other CNC machining services offered: 5-Axis Machining, 5-Axis CNC Machining, Multi-Axis Machining, 4-Axis Machining, 3-Axis Machining, Horizontal Milling, Vertical Milling, Horizontal Turning, Vertical Turning, CNC Engineering, CNC Inspection, and Special Machining Process

All product names, trademarks, and registered trademarks are the property of their respective owners.